printer who sets and corrects type

In the days before the computer, printing was done by hand, with all of the stages being carried out by different people.

Image source: https://www.youtube.com/

The first stage required a good knowledge of letterforms and a range of tools, including metal "chases" which held the letters in place; punches to make holes in them; and matrices to cast new ones.

Image source: https://www.amazon.in/

Linotype operators had to have specialized skills for casting molten lead into hot metal slugs for use in automatic typecasting machines.

Image source: https://www.croma.com/

Later on, after printing had begun on paper from movable type locked up as "formes", it often became necessary to proofread what had been set by eye while it was still damp and lift out any letters that had not properly taken their imprint.

Image source: https://www.flipkart.com/

After that, the line was printed from the oil lamp, and a skilled compositor would "line-up" the text by writing in the letters of a separate copy.

Image source: https://www.reliancedigital.in/

Once this stage was done, other people had to set the type again, but in a different way: not one at a time like linotype operators but with many hands working simultaneously and other people carefully adjusting their settings for good "fit".

Image source: https://www.vijaysales.com/

They might use different pieces of paper of different widths and weights or stitch multiple copies together into a "setting" book.

Image source: https://ipinterest.com/

They might also print upside down or in reverse to check that they were printing correctly and were not making any mistakes.

Image source: https://trustedreview.in/

Finally, the type would be locked up again as a forme and another proofread taken.

Image source: https://pinterest.com/

And they still had to make sure that there were no mistakes when it went to the printer: book printers did not use stereotyping to produce their books cheaply.

Image source: https://www.vijaysales.com/

Instead, they might produce only 20 or 30 copies at a time, using the best materials and taking their time. It was a labor-intensive business.

Image source: https://www.reliancedigital.in/

Many of these skills were lost with the advent of computerized typography and desktop publishing: it is often possible simply to replace one letter rather than setting up a new piece of type for every single character by hand. Do you need words printed in two colors?

Image source: https://www.flipkart.com/

A thousand copies fast? Somebody who can spot even the most minor error in your manuscript and make suggestions for improving it before publishing? I have been facing a conundrum since I started my new job.

Image source: https://www.croma.com/

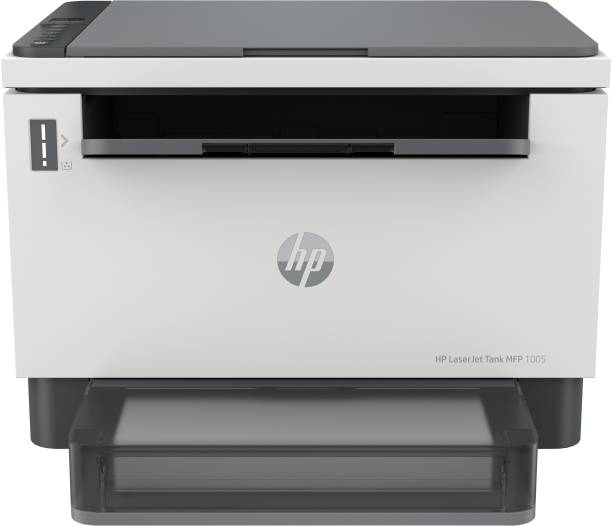

Now, it's not the worst job I've had, but it is the company priter for the office and I'm tasked with maintaining all of their printers in perfect condition. Now keep in mind that by "perfect condition" we are not going for "like new", so this is a different kind of problem from what many people might be used to.

Image source: https://www.amazon.in/

Williams Publishing Company, Inc. has been doing that since 1921. Working with the best minds and printers, we are a full-service printer from typesetting to binding, copying to book manufacturing, short runs to large volumes. No job is too big or small for us; whether you need 50 copies or 10 million.

Image source: https://www.youtube.com/

Our clients receive from us the highest level of service and personal attention. We suggest changes and changes your manuscript within our time limits, in a timely fashion...

.

Comments

Post a Comment